5 min read

In the rapidly evolving landscape of industrial equipment and manufacturing, the concept of modularization has gained substantial traction. Among the various modular and plug-n-produce approaches, the Modular Type Package (MTP) approach has emerged as a game-changer, offering unparalleled flexibility, scalability, and efficiency.

MTP, MODULARITY and PLUG-N-PRODUCE trajectory

The trajectory of MTP points toward its status as the industry standard. With its origins dating back 25 years and bolstered by numerous consortia, this concept has gained solid traction, particularly within process industries. By facilitating continuous processing through reduced changeover times and equipment vendor agnosticism, MTP has garnered substantial interest from end-users.

As biotech, pharma and chemical end-users strive to optimize their operations and adapt swiftly to changing market demands, POL (Process Orchestration Layer) and PEA (Process Equipment Assemblies) vendors find themselves at a critical juncture. As competition intensifies efforts to adopt this framework, its potential as a competitive differentiator becomes increasingly clear.

Ten imperatives

In this article, I delve into the crucial technological imperatives that PEA vendors need to embrace in order to create equipment modules that align seamlessly with the MTP approach. (Read more about the MTP framework here)

By understanding and implementing these imperatives, PEA vendors can unlock a competitive edge, streamline their production processes, and cater to the ever-growing demand for modular, adaptable, and interoperable industrial solutions. From design principles to integration aspects, this article serves as a comprehensive guide for PEA vendors to navigate the dynamic landscape of modular technology and emerge as leaders in the industry.

You can read more about the drivers and challenges of MTP adoption for Module Producers here.

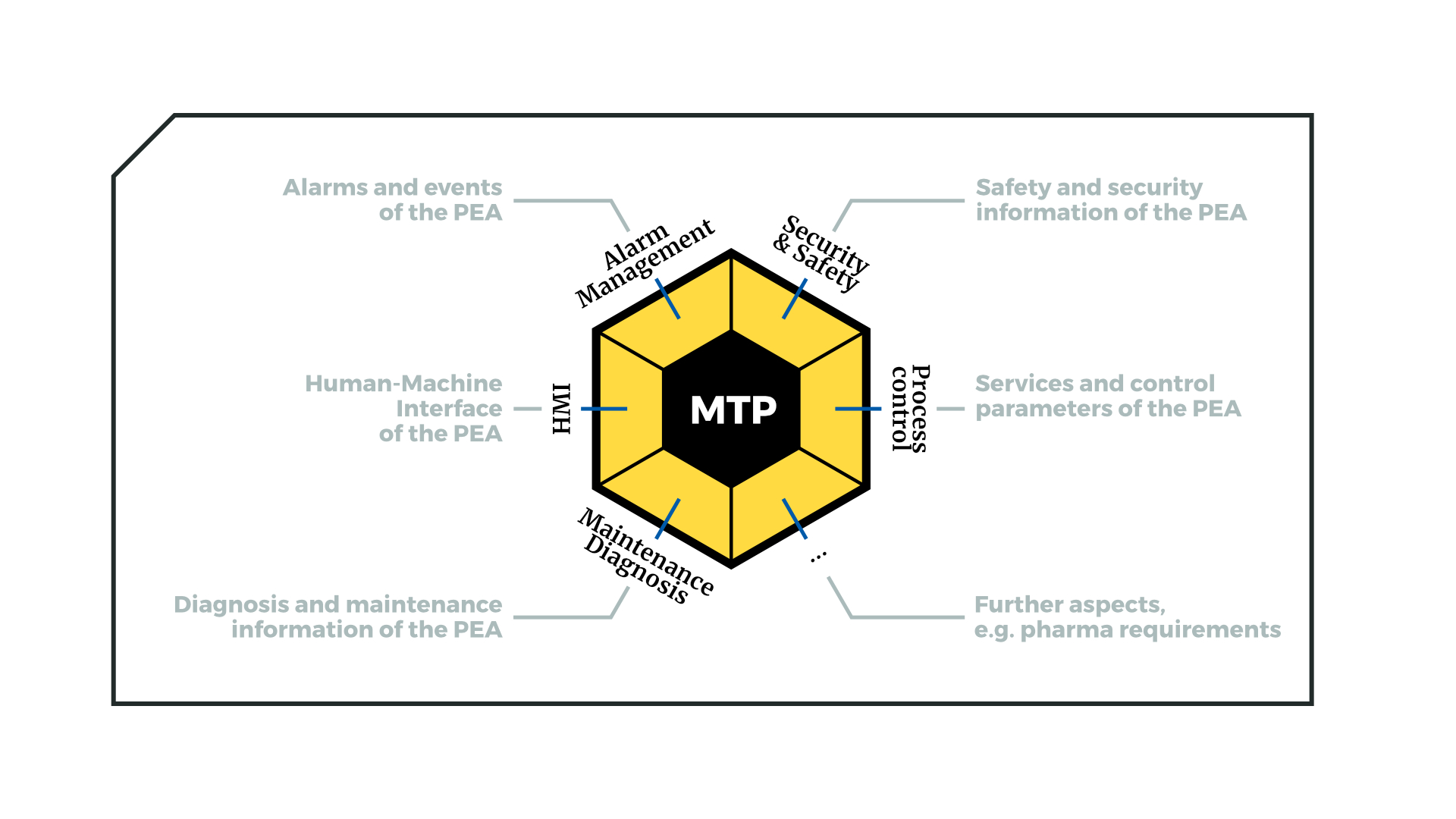

MTP Structure

MTP Structure diagram

- Alarm management – Alarms and events of the PEA

- HMI – Human-Machine interface of the PEA

- Maintenance Diagnosis – Diagnosis and maintenance of the PEA

- Security & Safety – Safety and security of the PEA

- Process control – Services and control parameters of the PEA

- Further aspects, e.g. pharma requirements

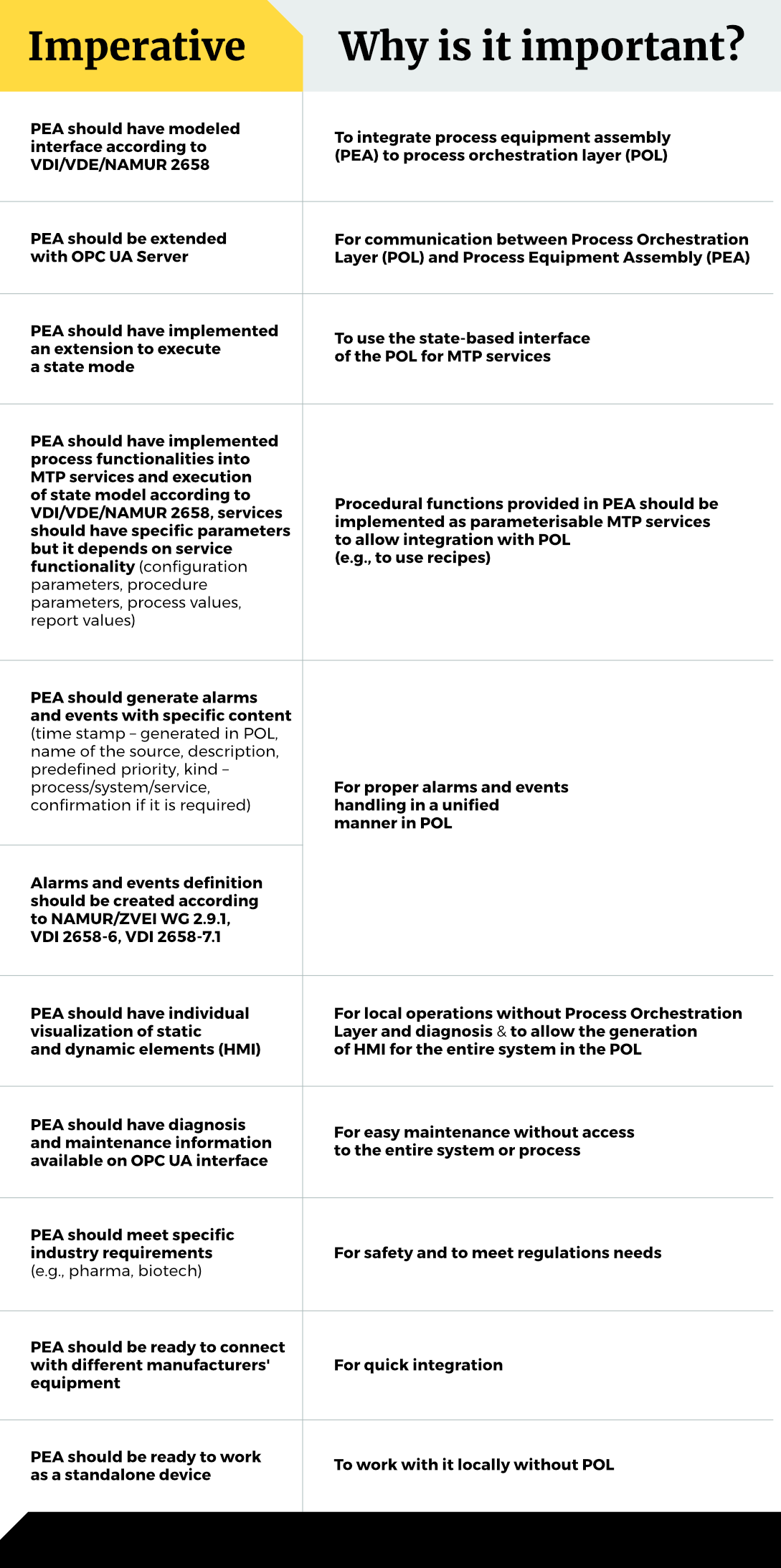

IMPERATIVES to create equipment modules compliant with MTP structure

| Imperative | Why is it important? |

|---|---|

| PEA should have modelled interface according to VDI/VDE/NAMUR 2658 | To integrate process equipment assembly (PEA) to process orchestration layer (POL) |

| PEA should be extended with OPC UA Server | For communication between Process Orchestration Layer (POL) and Process Equipment Assembly (PEA) |

| PEA should have implemented an extension to execute a state mode | To use the state-based interface of the POL for MTP services |

| PEA should have implemented process functionalities into MTP services and execution of state model according to VDI/VDE/NAMUR 2658, services should have specific parameters but it depends on service functionality (configuration parameters, procedure parameters, process values, report values) | Procedural functions provided in PEA should be implemented as parameterisable MTP services to allow integration with POL (e.g., to use recipes) |

| PEA should generate alarms and events with specific content (time stamp – generated in POL, name of the source, description, predefined priority, kind – process/system/service, confirmation if it is required) | For proper alarms and events handling in a unified manner in POL |

| Alarms and events definition should be created according to NAMUR/ZVEI WG 2.9.1, VDI 2658-6, VDI 2658-7.1 | |

| PEA should have individual visualization of static and dynamic elements (HMI) | For local operations without Process Orchestration Layer and diagnosis & to allow the generation of HMI for the entire system in the POL |

| PEA should have diagnosis and maintenance information available on OPC UA interface | For easy maintenance without access to the entire system or process |

| PEA should meet specific industry requirements (e.g., pharma, biotech) | For safety and to meet regulations needs |

| PEA should be ready to connect with different manufacturers’ equipment | For quick integration |

| PEA should be ready to work as a standalone device | To work with it locally without POL |

What’s next?

The MTP concept is now mature enough for PEA implementation by module vendors. Existing POL systems can already process MTP files and manage such PEAs effectively.

Although MTP is not yet widely adopted, it has the potential to become a standard rapidly. Those who are unprepared might fall behind, giving an advantage to early adopters.

At A4BEE, we are well-equipped with the necessary expertise, experience, and skills to guide you through your MTP journey. For more information, refer to our detailed A4BEE MTP offer.