6 min read

Introduction

In today’s widespread industrial process automation, companies often face the question of how to maximize profits. There are many answers, as it revolves around increasing a company’s competitiveness in a way that benefits it the most. How can this be achieved? There are numerous options and methods, one of which is automating energy management in industrial plants, which contributes to optimizing production costs. Many companies are investing in renewable energy sources (RES), but let’s look at another approach to reducing energy costs.

Increasingly, we are seeing how new technologies enable the world of OT and IT to intermingle. With modern energy management systems, it is possible to monitor the consumption of electricity, gas, or other energy carriers in real time. Artificial intelligence (AI) and machine learning (ML) allow for even greater optimization as these systems analyze vast amounts of data and learn energy consumption patterns.

This makes it possible to forecast demand more accurately and respond quickly to irregularities. Companies using artificial intelligence algorithms can automatically adjust the operation of machines and equipment according to energy consumption, avoiding energy waste and reducing costs simultaneously. Solutions of this type additionally make it possible to quickly detect areas of excessive consumption and take corrective action, leading to significant savings. Implementing appropriate automation tools reduces operating costs and increases the efficiency of production processes, which translates into greater competitiveness for the company in the market.

Energy Efficiency and Optimization Goals

Energy efficiency in industry means maximizing energy use with minimal losses. In manufacturing plants, all devices, machines, and installations should operate to use as little energy as possible while maintaining the same total efficiency. Through energy management automation, companies can monitor where and when energy is being used, allowing them to respond more quickly to unusual situations and improve the plant’s energy efficiency.

By automating energy management processes, companies can monitor where and when energy is consumed, allowing them to react more quickly in non-standard situations and to influence improvements in the factory’s energy efficiency.

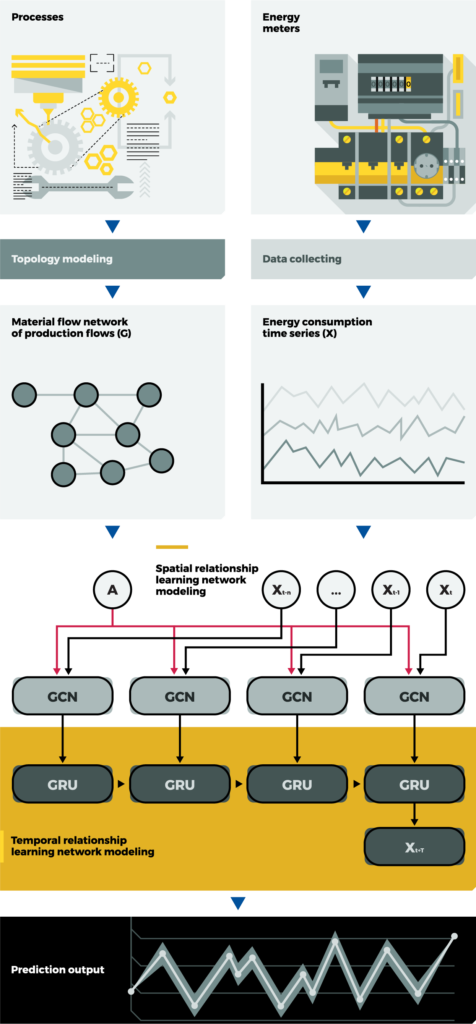

Before implementing a Machine Learning-based energy management system in a plant, it may be necessary to modernize the infrastructure using the Industrial Internet of Things (IIoT). Upgrading the plant’s infrastructure with IIoT can be very beneficial, and sometimes even essential, for effectively implementing machine learning-based energy management applications. IIoT enables real time data collection from various sensors and devices, which is crucial for ML applications that require large, accurate, and up-to-date datasets to predict energy consumption, optimize usage, and detect anomalies. The accuracy of predictions improves when data is collected from multiple sources in real time, which is often possible thanks to IIoT.

The Role of AI and ML in Energy Management

IoT provides vast amounts of data, creating the need to maximize its use. How can this be done? Artificial intelligence and machine learning can efficiently process this information and convert it into concrete actions. AI and ML allow companies to streamline processes and significantly reduce operational costs. By analyzing data in real time, these technologies help predict energy demand, prevent exceeding declared power, identify system inefficiencies, and prevent failures, improving network stability.

Implementing AI-based solutions can result in significant savings for both energy providers and end-users. Automating processes and precise data analysis help minimize energy losses and increase profits through more efficient resource management.

Energy Consumption Optimization Algorithms and Models

Various algorithms and models can be used in energy consumption optimization using AI and ML, helping to analyze data and make real-time decisions. Below are examples of machine learning models.

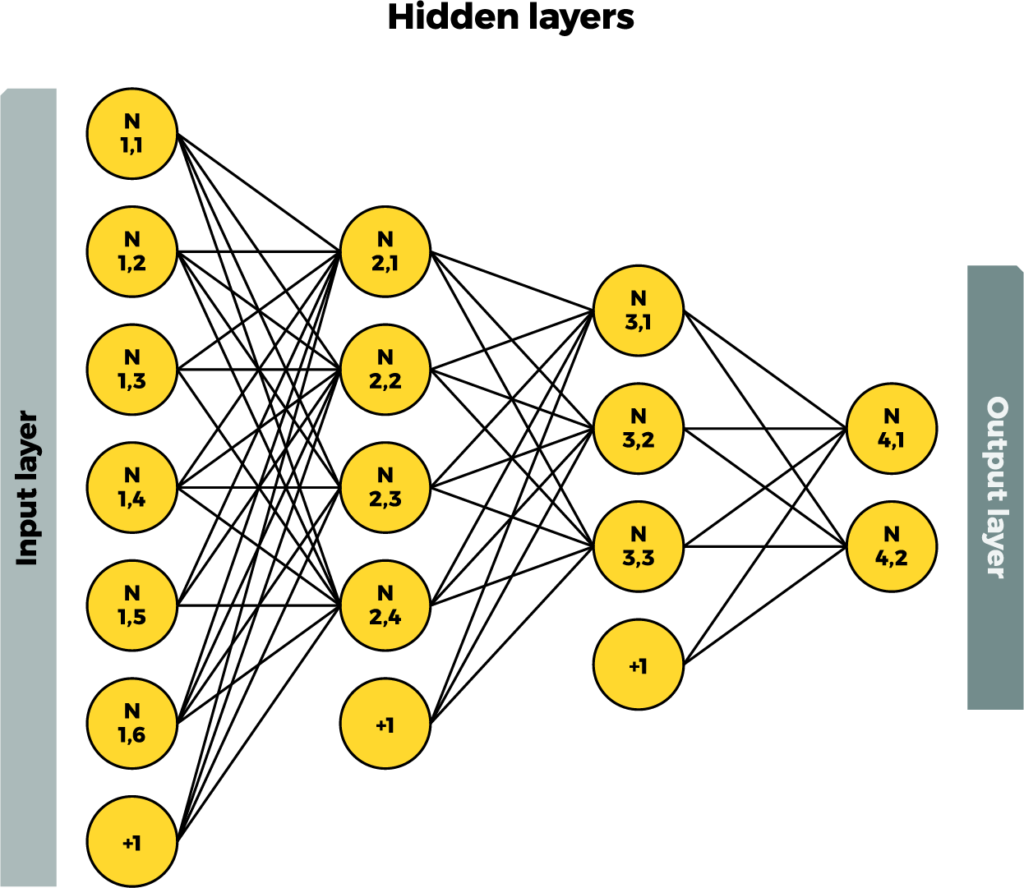

Neural Networks (ANN)

Used to analyze large datasets containing information on energy consumption and to predict future energy demand. These models can optimize production processes by considering energy consumption patterns. However, their downside is the increasing training time as the number of neurons in the network grows.

Deep Learning Algorithms

Models such as Recurrent Neural Networks (RNN) and Long Short-Term Memory (LSTM) are effective in analyzing time-series data (e.g., real time monitoring of energy consumption). They can predict future energy consumption peaks and adjust energy usage to meet needs.

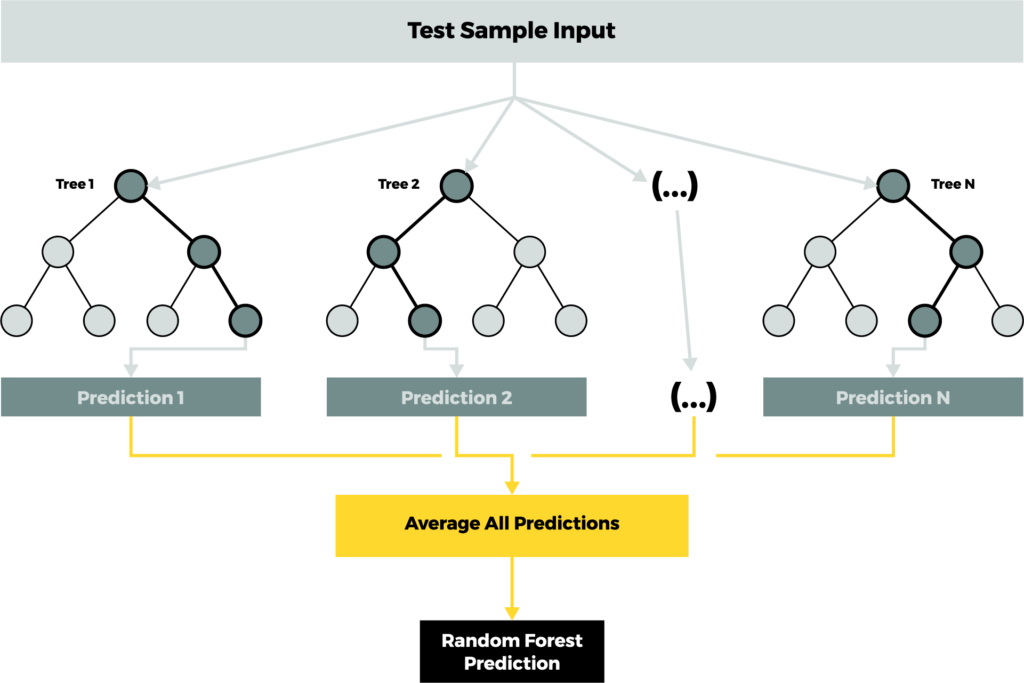

Decision Trees and Random Forests are flexible and easy-to-use algorithms that often produce excellent results without fine-tuning their parameters. They can help make decisions about switching off or reducing devices’ power.

Support Vector Machines (SVM)

Used for data classification and anomaly detection in energy consumption. They can help optimize device operation, minimizing unnecessary consumption.

Clustering Algorithms

Algorithms such as k-means can group devices or processes with similar energy consumption patterns to better adjust their operations. This is a commonly used algorithm in motor lifespan diagnostics.

AI Energy Management Systems in Practice

An excellent example of how an AI energy management system works is the Canal de Isabel II project in Madrid, where Siemens achieved an energy consumption reduction of 15–20%, resulting in significant financial savings. Siemens implemented predictive maintenance and process optimization, enabling early fault detection and better device management. This made the treatment plants more efficient while reducing energy-related operating costs by over 15%. Canal de Isabel II’s long-term savings include cost reduction and a significant decrease in greenhouse gas emissions, which have a major environmental impact.

Google pioneered using AI and ML to optimize energy consumption in its data centers. In one such center in the U.S., Google applied AI developed by DeepMind to manage cooling systems, one of the main components of energy consumption in these facilities. The AI analyzed vast amounts of data from systems monitoring temperature, humidity, and energy consumption, learning how to optimize the operation of cooling systems.

The implementation of AI reduced the energy required for cooling by 40%. These measures resulted in millions of dollars in annual savings on a data center scale. Google reports that the energy efficiency of the entire data center improved by 15%, which is a significant result given the scale of operations and the high costs of maintaining server cooling.

Summary

Optimal energy management brings many benefits, such as reducing operational costs, better resource utilization, and lower energy consumption, positively impacting a company’s market competitiveness. IoT and AI technologies enable automatic adjustment of device operations to actual needs, minimizing energy losses and improving efficiency. The advantage of such systems is their precision and quick response to changes. However, the downside may be the high implementation costs and the need for infrastructure modernization to leverage modern solutions’ potential fully.