Perfusion chamber for innovative microfluidics research

Industry

Life Science

Scope

Design / Implementation / Data integration

Timeframe

4 months

-

2

total project phases

-

4

months as a total duration

-

6

team members

01

CLIENT

The client is an academic research group based in Brussels, specializing in biomaterials and biochemical engineering.

Their work focuses on developing innovative materials for tissue engineering and exploring sustainable strategies to valorize biomass for biomedical applications.

Combining expertise in material science and biotechnology, the group aims to advance the field of regenerative medicine through interdisciplinary research and collaboration.

02

BUSINESS NEEDS

Ensure consistent fluid dynamics to achieve improved experimental precision, which leads to more accurate research results. Additionally, the solution is custom-tailored, featuring a chamber specifically designed to integrate seamlessly with the experiment's unique requirements.

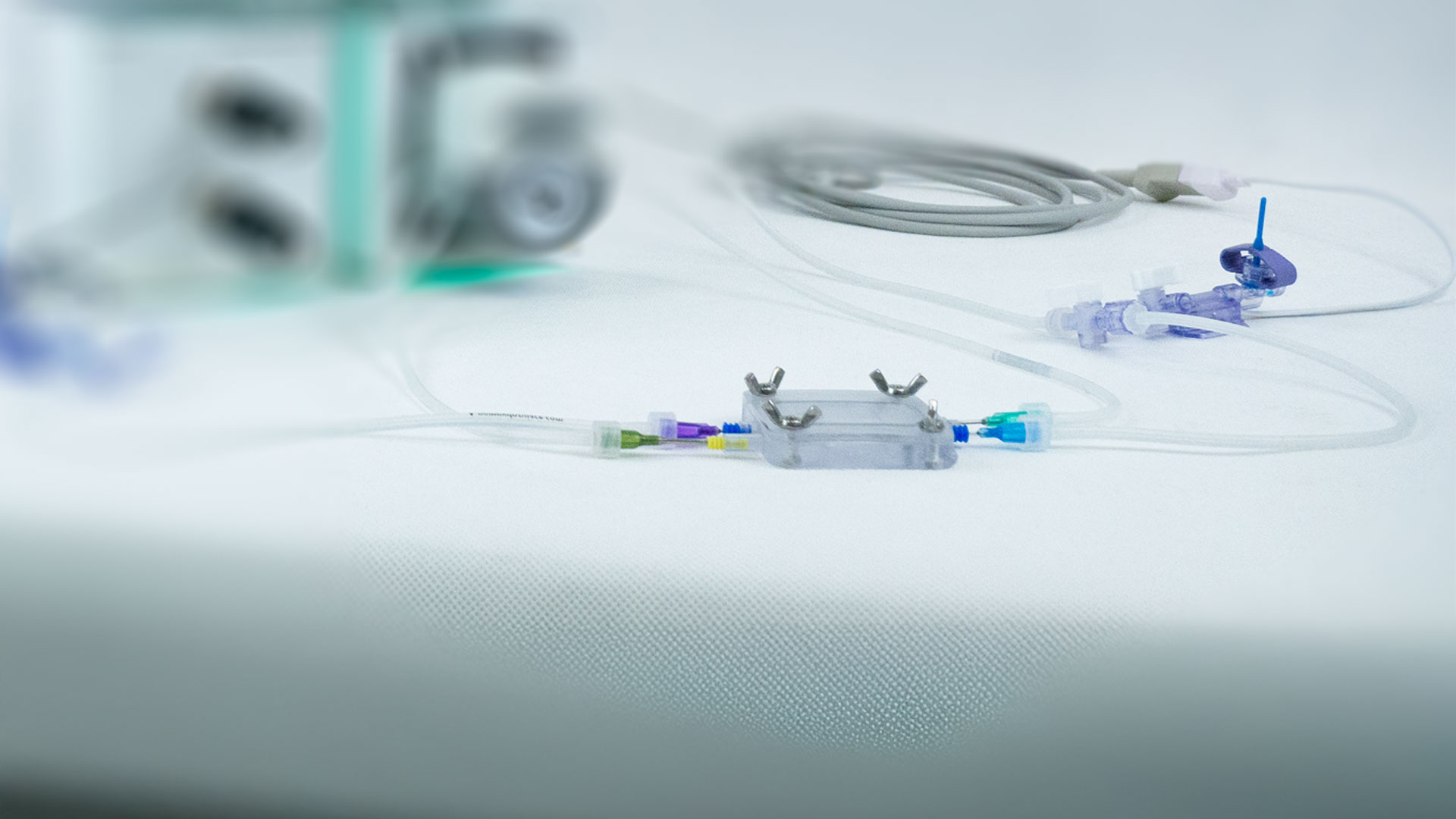

Our latest project focuses on the design, prototyping, and implementation of a perfusion chamber to support advanced laboratory research at ULB. This innovative system is designed to facilitate precise fluid dynamics in experimental settings, enabling accurate analysis.

03

CHALLENGE

To help our client achieve its goals, we overcome the following challenges:

-

Ensuring the setup remains stable and efficient over long durations without performance fluctuations.

-

The experimental setup should be mounted quickly and easily.

-

Precise fluid dynamics in experimental settings

04

SOLUTION

We provided a comprehensive solution for the design, development and deployment of a perfusion chamber system, tailored to support experimental research activities. The project covered the following key components:

- Comprehensive Graphical and Technical Design

- Functional 3D Prototype and Preliminary Test Results

- Test Results Using Specified Provided by ULB

- Remote Installation and Support for Laboratory

Development of detailed engineering schematics and 3D models. Ensuring compatibility with existing laboratory infrastructure and experimental protocols.

Production of a high-fidelity 3D prototype. Initial testing to validate core functionality and system stability.

Conducting performance evaluations with the hydrotube to confirm operational efficiency. Generating detailed reports on fluid flow dynamics and structural integrity.

Installation of the perfusion chamber. Providing remote technical assistance and guidance during the initial setup and operation at facility.

A dedicated team working towards a shared vision can drive remarkable progress. Precision and reliability are critical in laboratory research, and this project showcases how engineering excellence and collaboration can elevate experimental capabilities. We have created a system that enhances research efficiency and accuracy by integrating advanced design, fluid control solutions, and seamless installation. This is a step forward in supporting scientific discovery with cutting-edge technology.

Kinga Surmacz

Biotechnology Lead

Technology used

05

OUTCOME

We successfully developed a reliable and precise perfusion chamber, enhancing experimental accuracy and efficiency. But also...

- By optimizing the design, we ensured stable and controlled conditions for long-duration experiments.

- Researchers can focus on analysis rather than troubleshooting installation or fluid control issues.

- The system allows for seamless integration with existing laboratory setups, improving workflow efficiency.

- Remote support capabilities reduce downtime and enable smooth implementation at the facility.

06

IMPLEMENTED SOLUTION

-

Control of two peristaltic pumps and two pressure sensors

-

Data Collection and Visualization in Real Time

-

Remote monitoring and process control

-

User-friendly interface

-

2

total project phases

-

4

months as a total duration

-

6

team members