Increasing bioproduction

throughput with smart

modular photobioreactor

Industry

Biotechnology / Biomanufacturing

Scope

Modular Equipment / Data Integration / Laboratory Process / Small Scale Design / Software Engineering / User Interface Design

Timeframe

Approximately 2 months

-

12

weeks of creating an entire setup and dedicated control platform

-

55%

reduced manual work

01

CLIENT

R&D lab for small-scale microalgae culture.

02

BUSINESS NEEDS

In order to streamline the management of ongoing bioprocesses, the client wanted process data to be collected automatically, while at the same time allowing for an easy overview for the operator. Due to the many different potential processes carried out in the facility, it was important to flexibly adapt the equipment to current needs.

03

CHALLENGE

-

How can one utilize modular equipment that is controllable from a single platform to enable data visualization?

-

How to adapt parameters to the specific species of microalgae combined with efficient growth?

-

How to effectively collect and analyze bioprocess data?

-

How to easily customize the number and type of devices needed?

-

How to integrate the devices involved in the entire process?

04

SOLUTION

This solution allowed the client to improve the process of culture data management. Remote access and control allowed greater flexibility during operation. As a result of our work, the client received:

- Photobioreactor with configurable number of devices and central control unit

- A platform for process data collection with a user-friendly interface

- Remote access and control

The team has done a great job, and we are proud of our product. I believe that the solution we have developed will make it easier to manage any microorganism culture and significantly reduce the staff's workload involved in its maintenance. Efficient data management, flexibility in equipment selection, and remote monitoring are key features that provide peace of mind in day-to-day operations.

Kinga Surmacz

Biotechnology Consultant

Technology used

05

OUTCOME

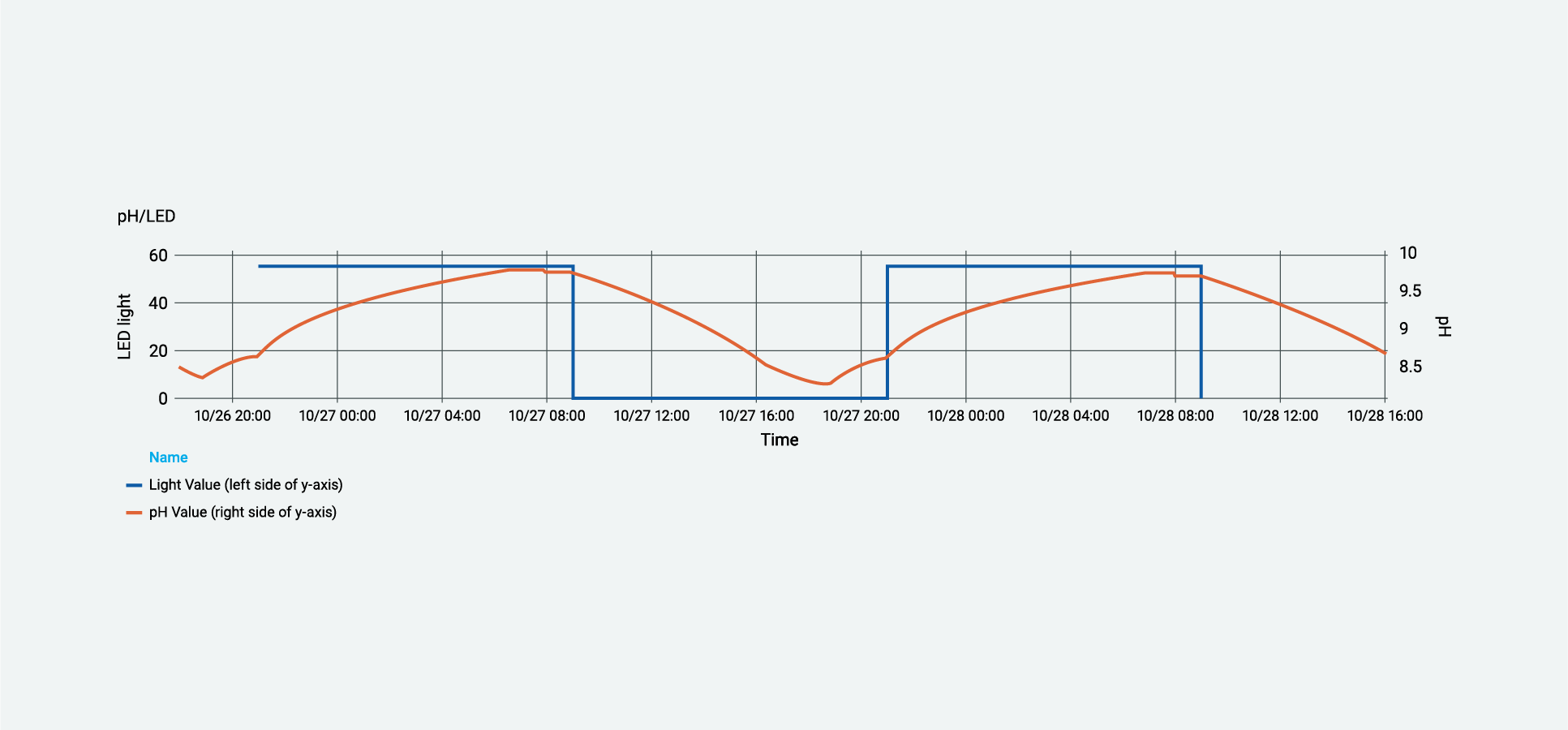

Fully functioning photobioreactor connected to a control platform enabling:

- Live bioprocess monitoring

- Bioprocess data storage and real-time visualization

- Historical data reports

- Remote access and remote control

- Setting and acknowledging alarms

The use of a new technological approach translates into specific benefits for the person supervising the culture:

- MTP-based modules can be easily added or replaced to quickly adapt to changing requirements

- The modular approach reduces the need for costly and time-consuming customizations

- Modules can be used for different tasks, increasing the use of resources

- Upgrades or maintenance can be performed on individual modules without affecting the entire production line or laboratory processes

-

12

weeks of creating an entire setup and dedicated control platform

-

55%

reduced manual work