Innovative connector for multiple scales in bioprocess

Industry

Biotechnology

Scope

Retrofitting / IT / OT / R&D

Timeframe

2 weeks

-

6

scales in one device

-

2

supported manufacturers

-

40

hours to support new device

01

CLIENT

Several companies from various industries expressed interest in this solution. One of them is a global brand conducting biotechnological and pharmaceutical research worldwide, actively working on breakthroughs such as a cancer vaccine. Another is a leading brand in automation solutions, active since the 19th century, driving industrial growth with a strong focus on digitization and Industry 4.0.

02

BUSINESS NEEDS

Numerous standard laboratory scales are close during a single extensive process or multiple smaller ones conducted nearby. Many of these scales have a simple communication interface, but to operate it, manufacturers offer dedicated devices that come with their limitations. Multiple scales often mean multiple devices. The business need was to aggregate all of this in one solution capable of collecting information from multiple scales simultaneously, which could be integrated with a central system to enable process optimization and automation.

03

CHALLENGE

To help our client achieve its goals, we faced the following challenges:

-

Support for scales from both Mettler Toledo and Kern

-

Multiple scales connected to a single device

-

Weight type recognition

-

Compatibility with communication standards (MQTT, OPC UA)

04

SOLUTION

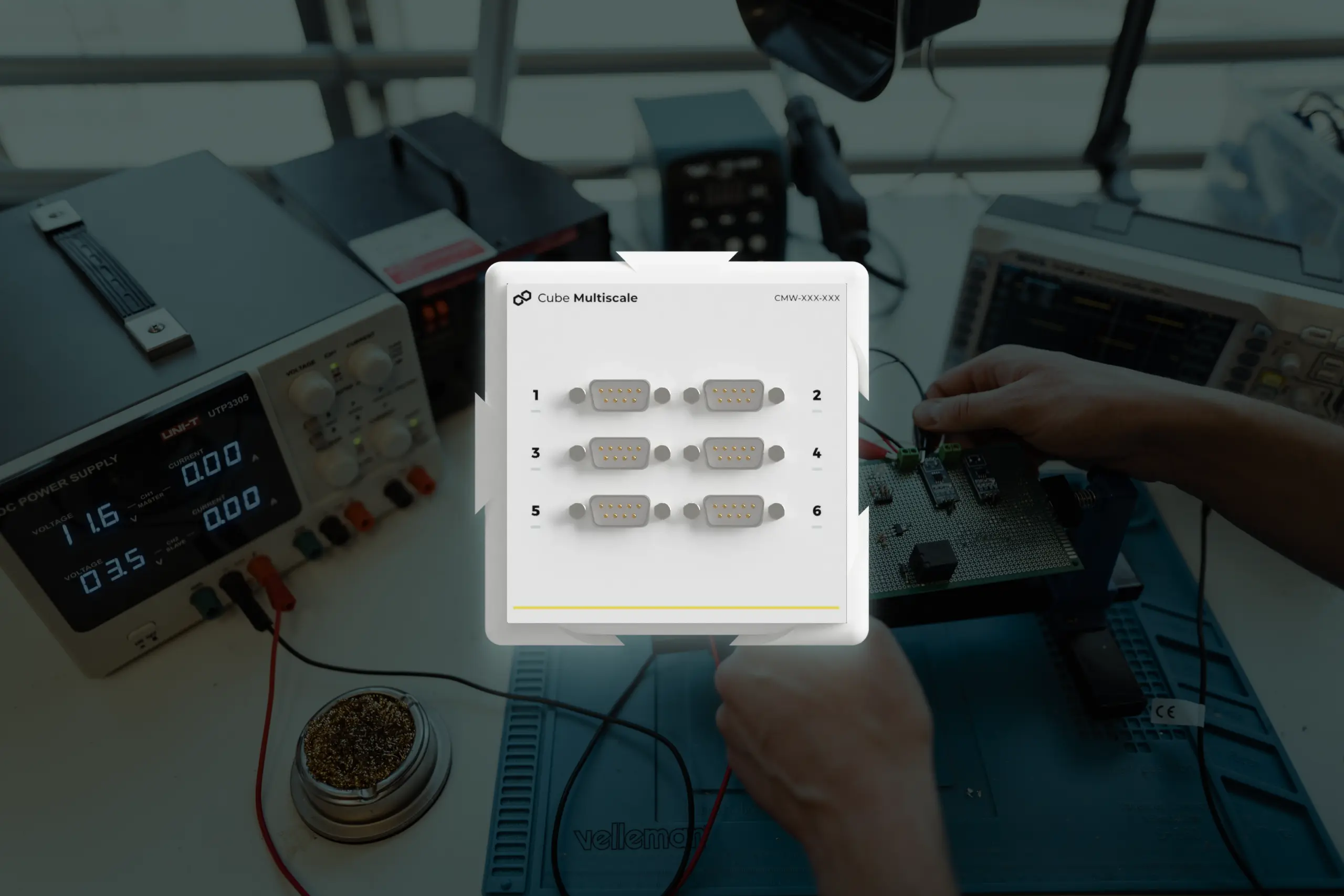

The solution is our Cube Multiscale. By combining CoreBoard® with our HATs, we can create a device with multiple communication ports, one for each scale.

- The number of supported scales can be easily increased.

- Implementing data reading from a new type of scale takes just a few hours.

- Efficient, scalable, and designed for quick adaptability!

The Kern scale is another piece of equipment that works seamlessly with our Cube ecosystem. Our Cube Multiscale can communicate with scales that use the RS232 communication. The Kern scale serves as a new alternative to the Mettler scale. Because our Cube can support different scales and displays data in an accessible format, work becomes simpler and more enjoyable.

Jakub Perliński

Embedded Developer

Technology used

05

OUTCOME

Cube Multiscale allows simultaneous data reading from six Mettler Toledo and Kern scales.

- The Cube occupies minimal space.

- Power and communication are handled through a single Ethernet cable using Power over Ethernet (PoE) technology.

- Data transmission to the system is supported via MQTT or OPC UA protocols

- Compliance with the MTP namespace ensures quick and easy integration.

- With CoreBoard®, standard scales can be transformed into digitally-enabled devices.

- This digital enhancement supports improved process optimization and analysis.

-

6

scales in one device

-

2

supported manufacturers

-

40

hours to support new device