Automated Cell Line Control with Advanced PAT

Industry

Pharma / Biotech

Scope

Process Orchestration / PAT Modeling / Automation / Data Science

Timeframe

4 months

-

60%

experiment reduction time

-

80%

manual process steps removed

-

6

standalone equipments integrated

01

CLIENT

A leading biopharmaceutical innovator focused on advanced monoclonal antibody (MAb) production and the implementation of state-of-the-art perfusion bioprocessing.

02

BUSINESS NEEDS

The client aimed to build a state-of-the-art perfusion cell line for MAbs to increase overall product quality. This required deep collaboration with vendors to develop new Process Analytical Technology (PAT) methods and a thorough understanding of the commercialization potential of integrated lab setups.

03

CHALLENGE

To help our client achieve data unity, we overcame the following challenges:

-

Quality Management

Increasing product (MAb) quality by actively managing complex protein glycosylation profiles. -

Complex Automation

Automating a perfusion bioprocess that leverages advanced liquid chromatography and mass spectroscopy (LS/MS) PAT models. -

Interdisciplinary Coordination

Managing multiple streams of work across process research, data analytics, and system integration. -

Distributed Collaboration

Coordinating efforts across a distributed team located in multiple sites across the EU and USA.

04

SOLUTION

We delivered a fully integrated laboratory ecosystem that utilizes a central process orchestrator and closed-loop control to stabilize MAb glycosylation profiles. The solution entailed:

- Advanced Data Platform Creation of a centralized data platform with advanced visualization capabilities to monitor process parameters.

- Central Process Orchestration Implementation of a Process Orchestration Layer (POL) to manage the entire lab cell line.

- Closed-Loop Control Development of an automation framework based on integrated PAT models to enable real-time process adjustments.

- Team Integration Deployment of a specialized team of scientists, engineers, and technicians to handle complex technical requirements.

Achieving high-quality monoclonal antibody production at scale requires more than just advanced hardware; it demands the perfect orchestration of data, science, and automation. By integrating state-of-the-art LS/MS glycosylation profiling with a central Process Orchestration Layer, we moved from simple monitoring to true closed-loop control. This project highlights our ability to manage multiple complex workstreams, from deep process research to global system integration, ensuring that every technical hurdle is transformed into a quantifiable increase in product quality and operational efficiency.

Łukasz Paciorkowski

CEO A4BEE

Technology used

05

OUTCOME

The implementation successfully transformed a complex, manual research process into a fully integrated, high-precision bioprocessing environment. By closing the loop between analytical data and process control, we delivered a system capable of autonomous process parameters optimization.

- Real-Time Quality Assurance Active management of protein glycosylation profiles resulted in MAb consistency meeting the highest pharmaceutical standards.

- Operational Autonomy Transitioning to closed-loop automation reduced manual sampling, minimizing contamination risks and human error.

- Accelerated Research Harmonizing the lab cell line through a central orchestrator allowed for faster experiment iteration and reliable data correlation.

- Commercial Readiness Provided a scalable blueprint for perfusion bioprocessing, offering a clear path for global commercialization.

06

IMPLEMENTED SOLUTION

-

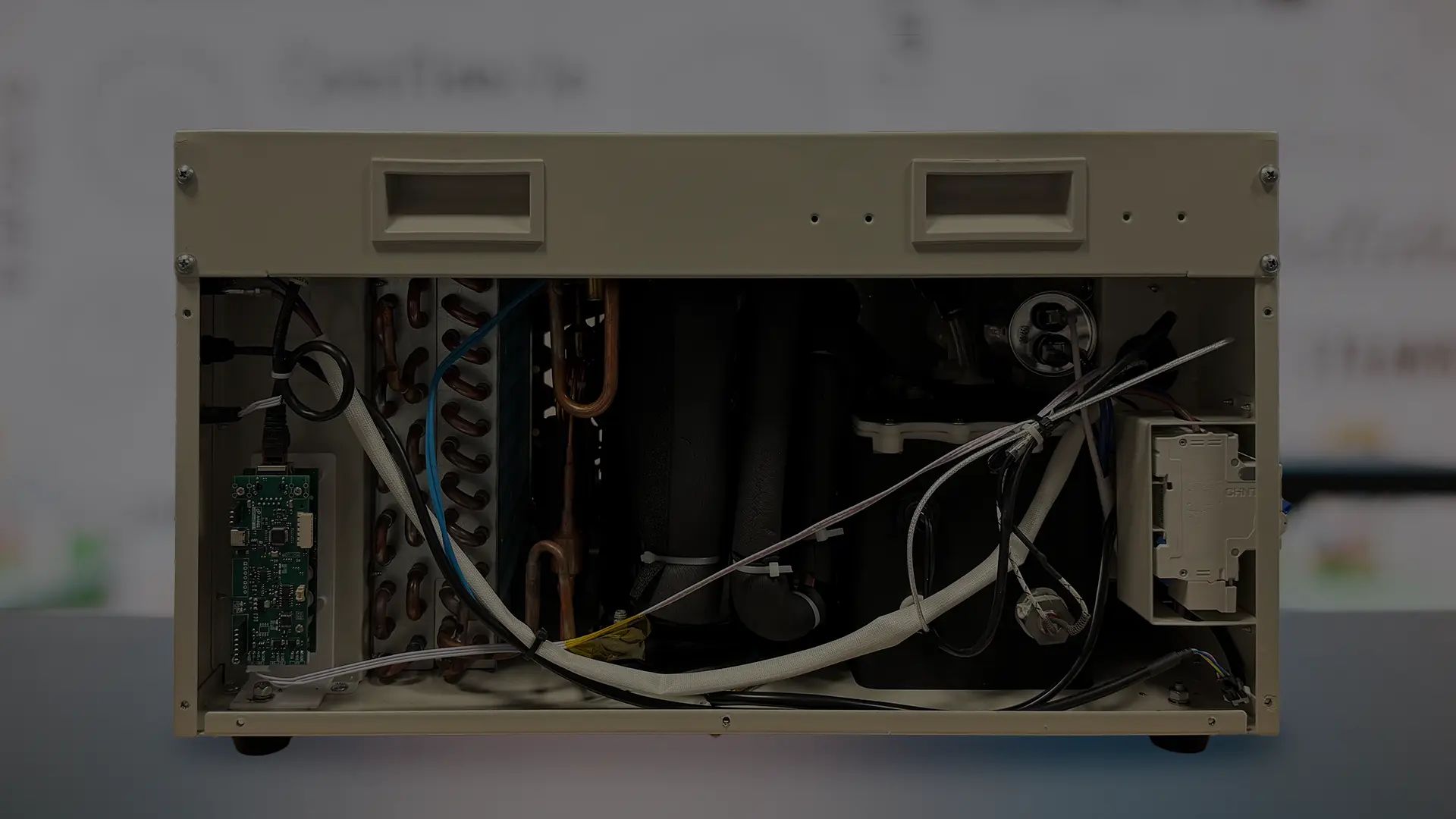

Automated Perfusion Control

Real-time management of bioreactor parameters based on sampling data. -

Aseptic Sampling Integration

Seamless connection between the auto-sampler and analytical instruments. -

PAT-Based Model Integration

Using advanced data models to drive the Process Orchestration Layer. -

Global Project Management

Execution through a distributed EU/USA team across multiple work streams.

-

60%

experiment reduction time

-

80%

manual process steps removed

-

6

standalone equipments integrated