Product Acceleration Lab

Transform your hardware concept into a market-ready product with agile development and in-house engineering.

Moving from a prototype to a commercial product is where most hardware teams struggle. We bridge that gap by combining rapid iteration, modular architecture, and full-stack technical support. Our lab handles everything from electronics and mechanics to firmware and software, ensuring your product is not just a working concept, but a verified, high-quality solution ready for the real world. We help you skip the "hardware is hard" traps and reach the market with confidence.

01

PAIN POINTS

Is your product growth stalled by fragmented vendors and slow cycles?

Managing separate partners for hardware, software, and testing creates communication gaps that lead to costly delays and technical debt.

-

Vendor Silos

Dealing with separate partners for HW, FW, and SW causes integration friction and delays market entry.

-

Iteration Lag

Traditional hardware development cycles are too slow, making it impossible to pivot based on user feedback.

-

Scaling Hurdles

Non-optimized BOMs and poor design for manufacturability (DfM) make scaling from MVP to pilot production too expensive.

-

Certification Walls

Late-stage discovery of compliance issues leads to major redesigns and months of missed revenue.

-

Technical Blind Spots

Lack of structured validation and testing leads to "black box" failures once the product is in the customer's hands.

02

OUR APPROACH

We merge rapid prototyping with industrial-grade validation.

We don’t just build prototypes; we engineer pathways to commercial success. By applying agile workflows to hardware development and keeping our lab services in-house in the EU, we reduce development risk and shorten the design-test-redesign loop by up to 50%.

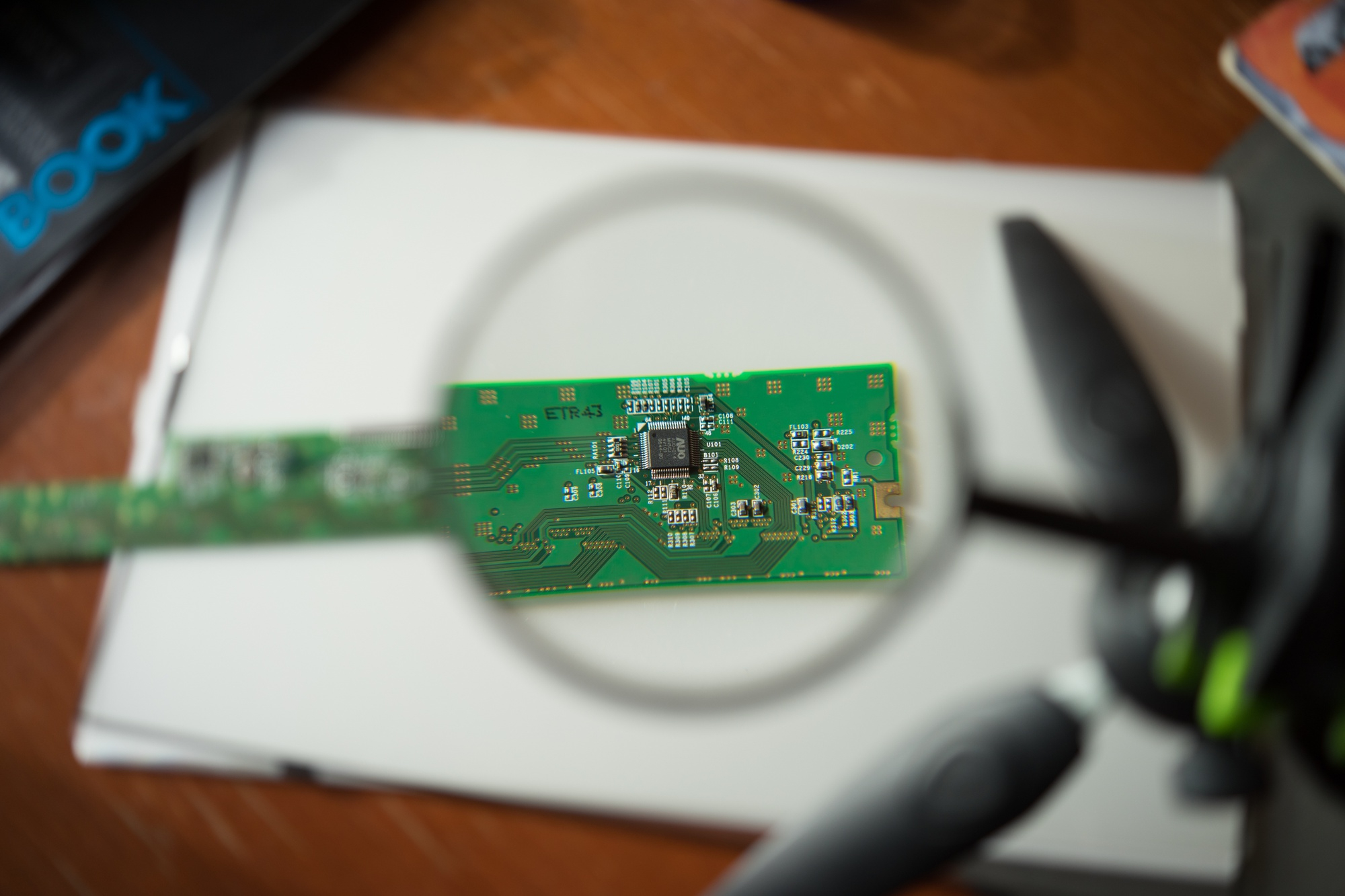

Design & Rapid Prototyping

Design & Rapid Prototyping

- Multidisciplinary engineering: Electronics, Mechanics, and Firmware.

- Rapid PoC (Proof of Concept) and MVP iteration cycles.

- Modular hardware architecture for future-proof scaling.

- Technical feasibility studies to de-risk development early.

- User-centric design for physical device interfaces (HMI/UI).

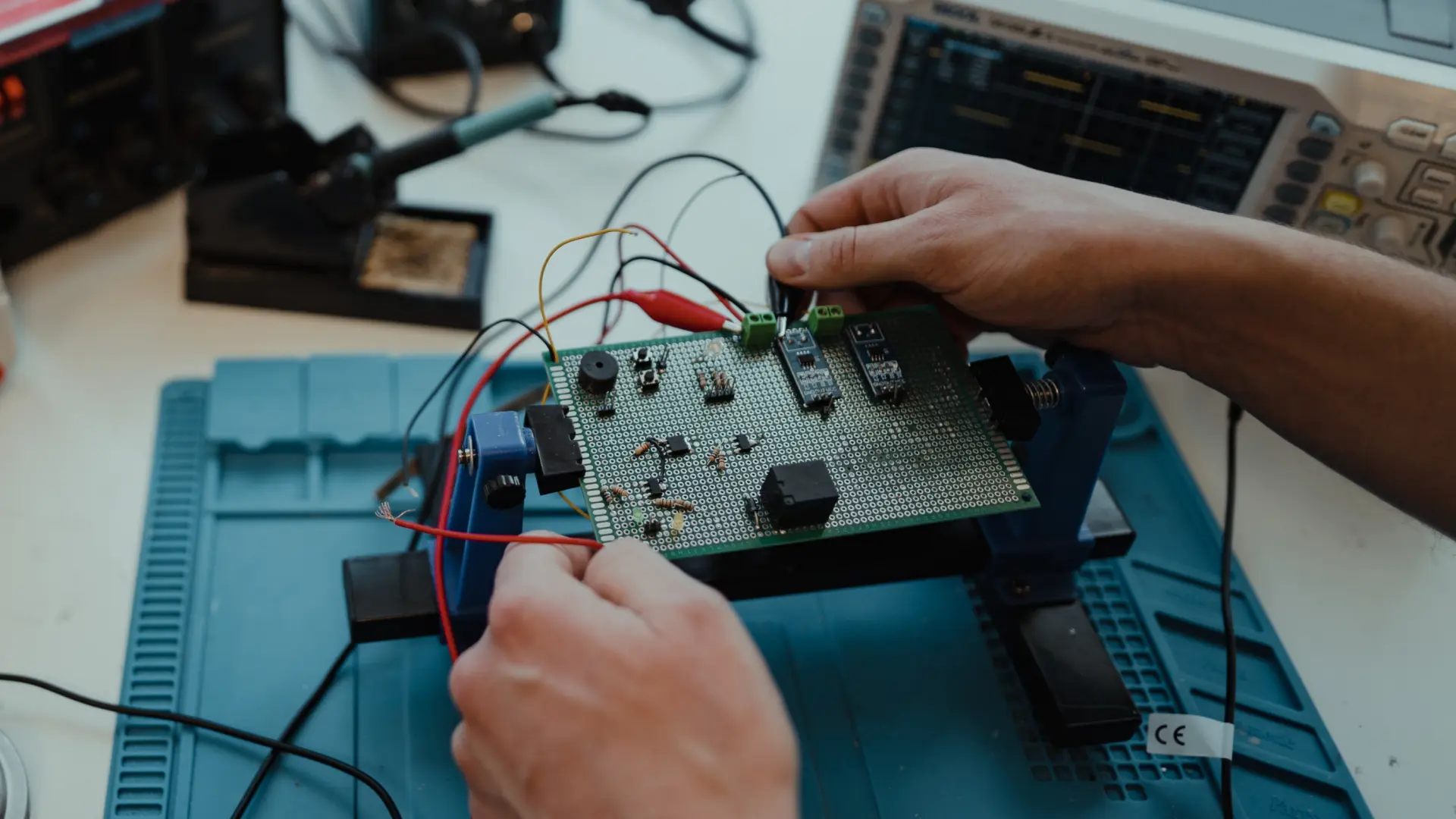

Validation & Lab Services

Validation & Lab Services

- In-house lab testing for specialized hardware and liquid handling.

- Environmental and stress testing for technical validation.

- Pre-compliance testing (CE readiness and norm analysis).

- Full documentation for regulatory approval pathways.

- Rigorous QA protocols before moving to pilot series.

Industrialization & Scaling

Industrialization & Scaling

- Design for Manufacturing (DfM) to optimize production costs.

- BOM (Bill of Materials) optimization and component standardization.

- Low-volume pilot production for early market validation.

- Complete tech-transfer and manufacturing support.

- Ongoing lifecycle management and hardware stabilization.

03

EXPECTED VALUES

Accelerate your path to a verified commercial product.

-

30–50% Faster Time-to-MVP

Our modular design approach and compressed design-test-redesign cycles let you launch while your competitors are still stuck in planning. -

End-to-End Predictability

Everything happens in our EU-based lab. No fragmented vendors, no communication gaps—just a coherent process from concept to pilot production. -

20–30% Cost Reduction

We optimize your product’s architecture and BOM early on, preventing expensive redesigns and stabilizing your margins before you scale. -

Structured Path to Market

We handle pre-compliance and norm analysis from day one, cutting through certification red tape and speeding up approval cycles by up to 50%.