Automated photobioreactors

for scaling

biomanufacturing

Industry

Biotechnology / Biomanufacturing

Scope

Industrial Design / Industrial Automation / Industrial Engineering / User Interface / Software Engineering / Data Integration / MTP / MQTT / Node-Red / IoT

Timeframe

8 months from scratch to fully functioning device and control platform

-

15%

increase in bacteria growth

-

100%

fully automated control platform

-

2

reactors commissioned

01

CLIENT

Innovative Poland-based biotech startup with expertise in microbiological culturing, process design, scale-up of new technologies.

02

BUSINESS NEEDS

To harvest more cyanobacteria-sourced bioproducts in a cost-effective way to meet customers expectations and speed up time-to-market.

03

CHALLENGE

How to use new technologies to scale up the production of molecules harvested from single-cell microorganisms?

-

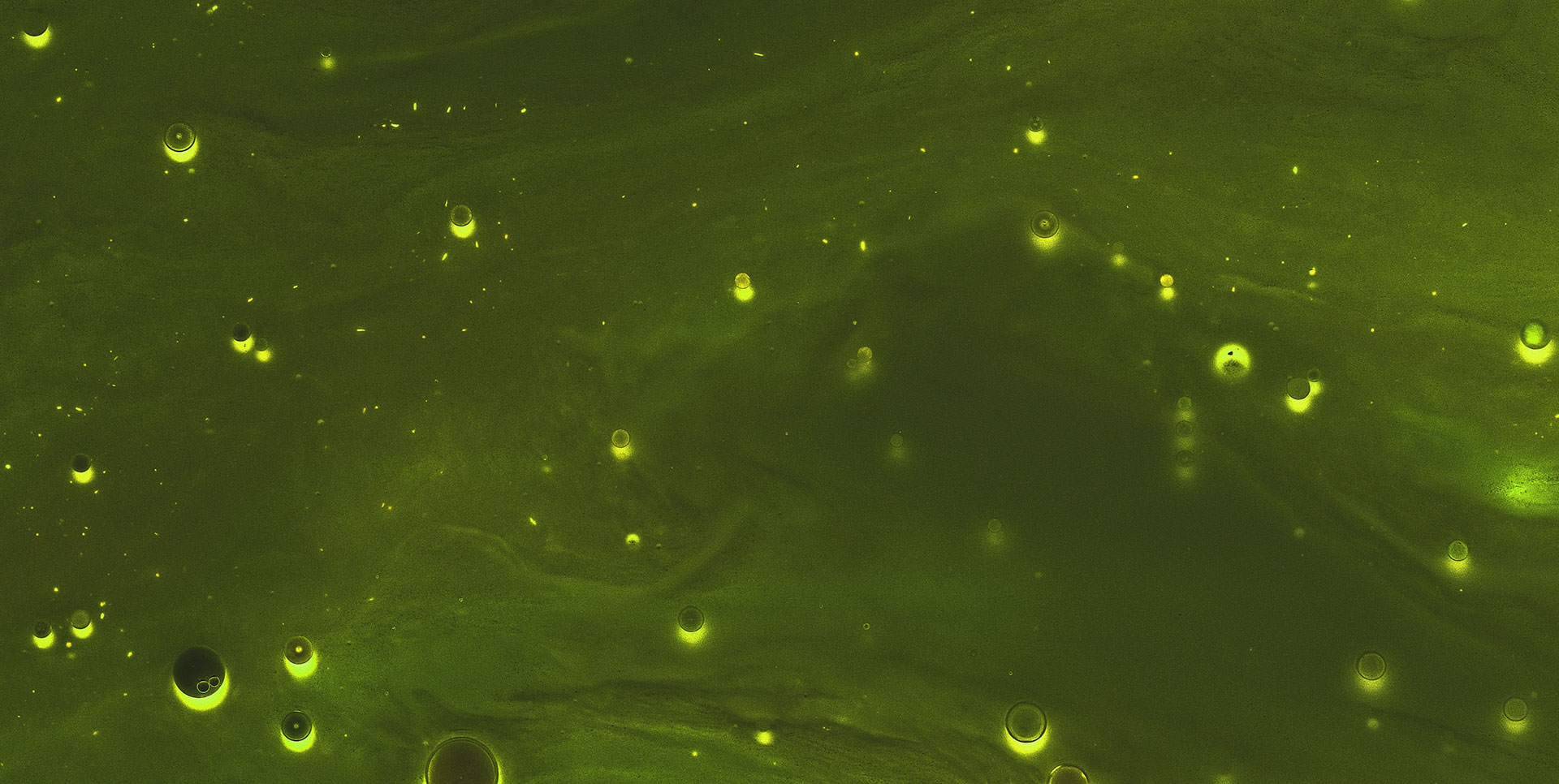

To adapt sahara-based cyanobacteria to a continuous biomanufacturing scaled up process

-

To increase the culture volume from 1 to 5 m3 while maintaining optimal parameters

-

To enable process-specific lighting spectrum

-

To optimize cultivation parameters

-

To automate biomanufacturing wisely and reduce the share of human labor

04

SOLUTION

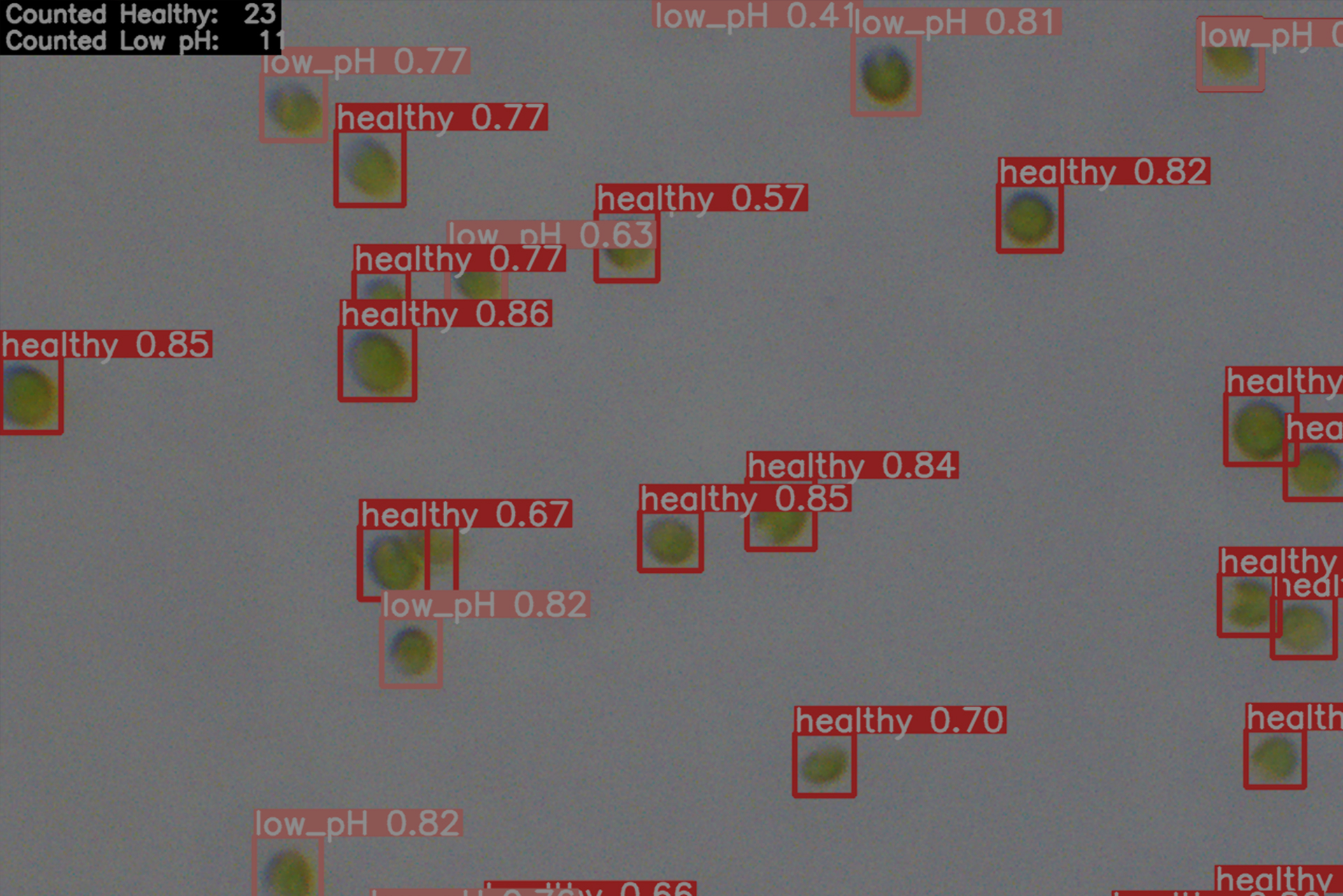

A comprehensive suite of tailored solutions was developed to address the unique needs of our clients, including

- Custom photobioreactor addressing specific requirements for cyanobacteria growth designed and manufactured

- Customized lighting solution supplying specific light spectrum constructed

- Modular automation platform managing the easily scalable fleet of 20+ bioreactors developed

- User-friendly bioprocess monitoring implemented

- Remote access and control achieved

Interdisciplinary team of experts

Industrial engineers, software developers, biotechnology consultants and project managers have worked side by side to achieve full functionality of the solution.

What our device is supposed to keep alive is priceless. The cell culture was intensively grown in the laboratory for many months before it was transferred to the photobioreactor. That's why we are extremely proud of our team's success.

Monika Gościniak

Project Owner

Technology used

05

OUTCOME

Fully functioning photobioreactors connected to a control platform enabling:

- Live bioprocess monitoring

- Bioprocess data storage and analysis

- Historical data reports

- Remote access and remote control

- Setting and acknowledging alarms

- Informing via text messages

- Energy consumption record

-

15%

increase in bacteria growth

-

100%

fully automated control platform

-

2

reactors commissioned