Custom submersible light modules for Photobioreactor

Industry

Industrial Biotech / Life Sciences

Scope

Hardware Engineering / IT/OT Integration / Multi-Spectral Lighting / Submersible Electronics / Scale-up

Timeframe

3 Months

-

3

Custom Spectral Profiles with different wavelengths

-

5,000L

Operational Depth Capacity

-

IP68

Submersion Rating

01

CLIENT

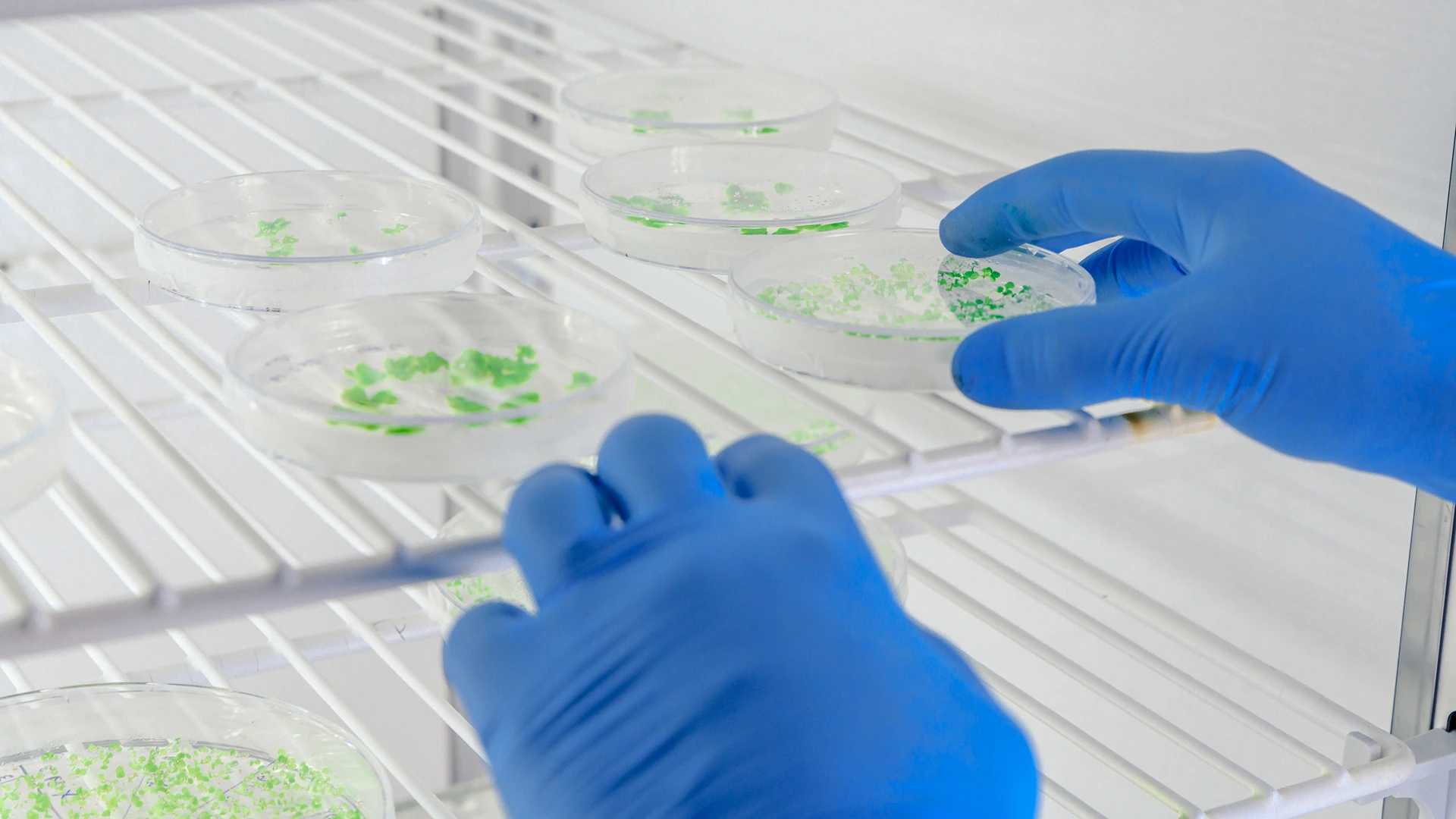

A Global Life Sciences innovator specializing in sustainable, bio-based protective compounds looking to leverage ancient evolutionary mechanisms of photosynthetic microorganisms.

02

BUSINESS NEEDS

The client aimed to scale from shallow, sunlight-dependent cultivation to high-density mass production within 5,000L photobioreactors by replacing inefficient external lighting with a specialized, industrial-scale internal solution powered by precise, high-intensity radiation.

03

CHALLENGE

To help our client achieve its goals, we overcome the following challenges:

-

Environmental Resilience

Engineering "water-sealed" modules capable of continuous operation while fully submerged in 5,000L bioactive environment. -

Spectral Precision

Delivering three distinct, mission-critical light ranges with laboratory-grade accuracy to trigger specific metabolic pathways. -

Thermal Management

Dissipating heat generated by high-power LED arrays within a sealed PMMA enclosure to prevent culture overheating and LED degradation. -

UV Light Transmittance

Finding a way to ensure high light transparency at the UV edge without using traditional borosilicate glass.

04

SOLUTION

We engineered a modular, submersible lighting architecture featuring custom-designed three-wavelength light modules, optimized for deep-tank integration. The solution entailed:

- Multi-Spectral Induction Deployment of three specialized module types with wavelengths close to UV to allow granular control over biomass growth.

- Advanced Encapsulation Technology Design of custom-machined PMMA tubes with industrial-grade seals and 3D-printed structural components.

- Active Internal Cooling Integrated high-efficiency fan modules within the sealed tubes to manage thermal loads and ensure stable output.

- High-Durability UV Optics Utilizing specialized UV-transparent PMMA instead of fragile borosilicate glass to ensure maximum light transmission.

By moving the light source directly into the heart of the bioreactor, we've bypassed the physical limits of traditional cultivation. This system moves beyond simple illumination to provide precise control over evolution at scale.

Marcel Domagała

Head of Digital Lab

Technology used

05

OUTCOME

The implementation enabled the client to transition from laboratory prototypes to a full-scale industrial production model. The custom internal lighting significantly increased the concentration of bioactive compounds by ensuring every liter of the 5,000L tank received the optimal spectral recipe.

- Yield Optimization Increase in biosynthesis yield due to precise UV stress induction.

- Full Submersion Full Submersion Capability in 5,000L tanks, eliminating external light loss.

- Future-proof Design Modular design allowing for rapid spectral adjustments for different bacterial strains.

- Industrial Scale Transition from lab-scale prototypes to full-scale industrial production models.

06

IMPLEMENTED SOLUTION

-

Advanced UV Optics

Specialized UV-transparent PMMA selected through laboratory testing for superior transmission and chemical inertness. -

Hybrid Illumination

Combination of fluorescent and LED sources designed to target specific bacterial absorption peaks. -

Flicker-Free Power

Deployment of specialized constant-current drivers to ensure stable radiation flux for sensitive pathways. -

Modular Automation

Full system integration via proprietary modular software for precise spectral control and scalability.

-

3

Custom Spectral Profiles with different wavelengths

-

5,000L

Operational Depth Capacity

-

IP68

Submersion Rating